01

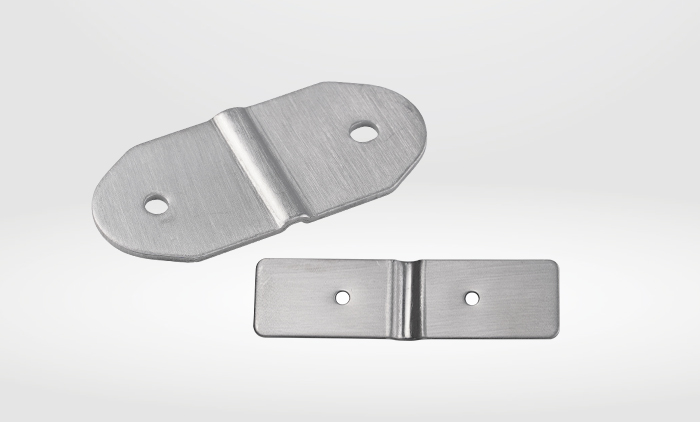

Aluminum Foiled Flexible Busbar

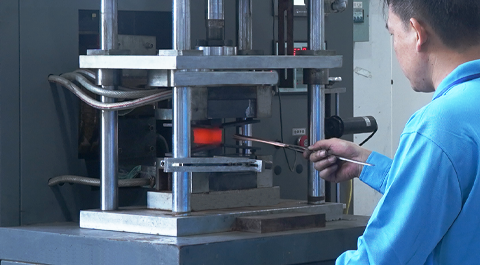

Aluminum Foiled flexible busbar refer to the busbar as a composite of several layers of 0.lmm or 0.2mm thick aluminum foil. The structure of the busbar has two separated areas: solid and flexible.The solid area is welded by molecular diffusion welding machine and it is for cell/module connection in battery pack. The flexible area is not be welded during manufacture process and it will be beneficial for assembly and reliability for vibration.

READ MORE